At Conprofe, we pride ourselves on being a leading ultrasonic machining manufacturer and CNC machine supplier dedicated to providing holistic CNC machining solutions to diverse industries worldwide. We’re committed to deliver high-quality CNC machining solutions tailored to meet unique requirements of hard-to-cut and hard-brittle materials. Additionally, we boost three production lines ranging from CNC parts, units to machine tools, providing not only machining centers, but also various CNC machining tools and accessories like solid PCD tools and micro-edge end mills.

As a trusted CNC machining manufacturer, we have a team of skilled engineers and technicians, that’s why we’re capable of not only milling machine manufacturing andultrasonic machining solutions but also providing a wide range of services, including free proofing services.

And we welcome CNC machine dealers from all over the world. Partner with Conprofe for all your CNC machining needs and experience the difference that quality, reliability, and expertise can make. Contact us today to learn more about our services and how we can support your business’s success as one of the leading machining center manufacturers.

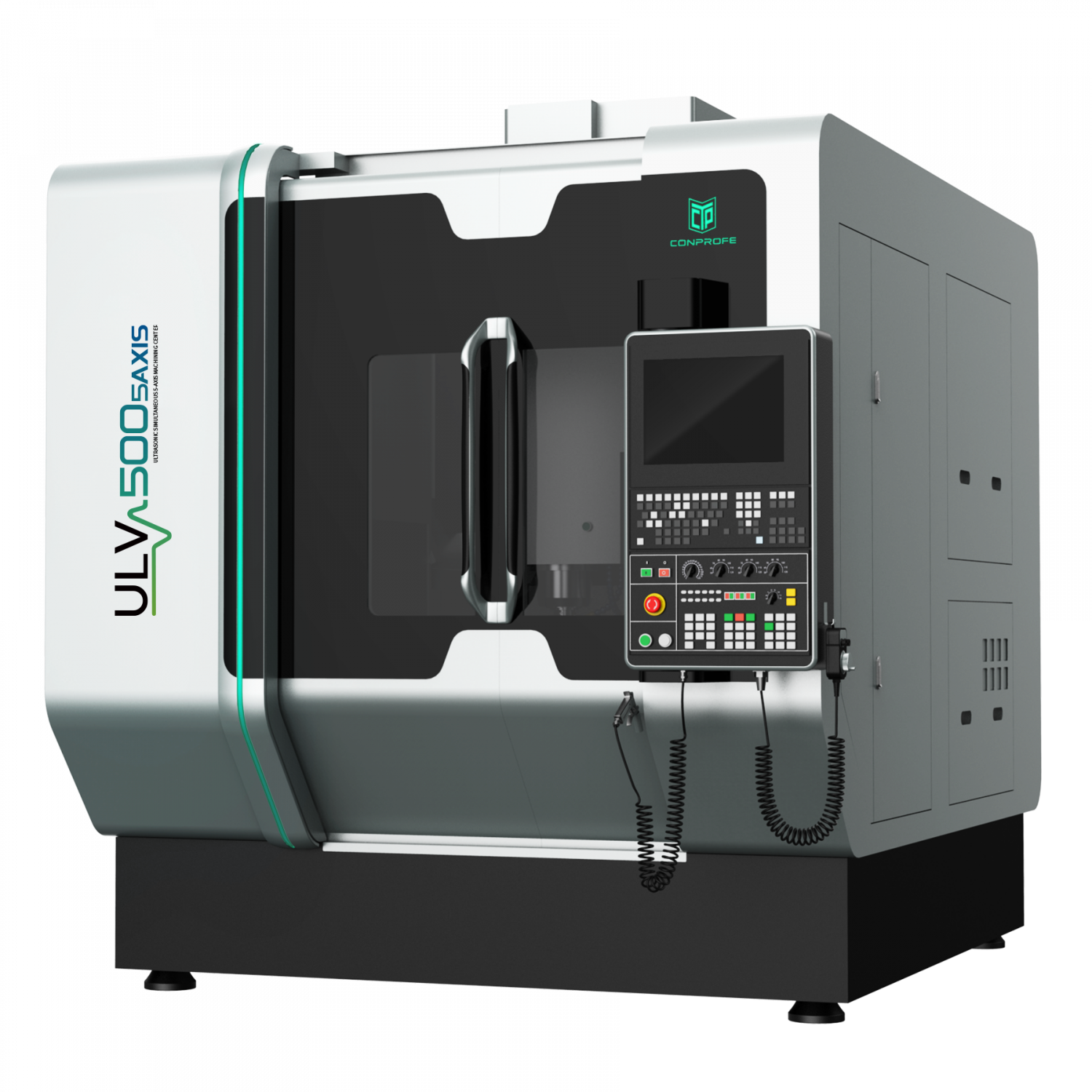

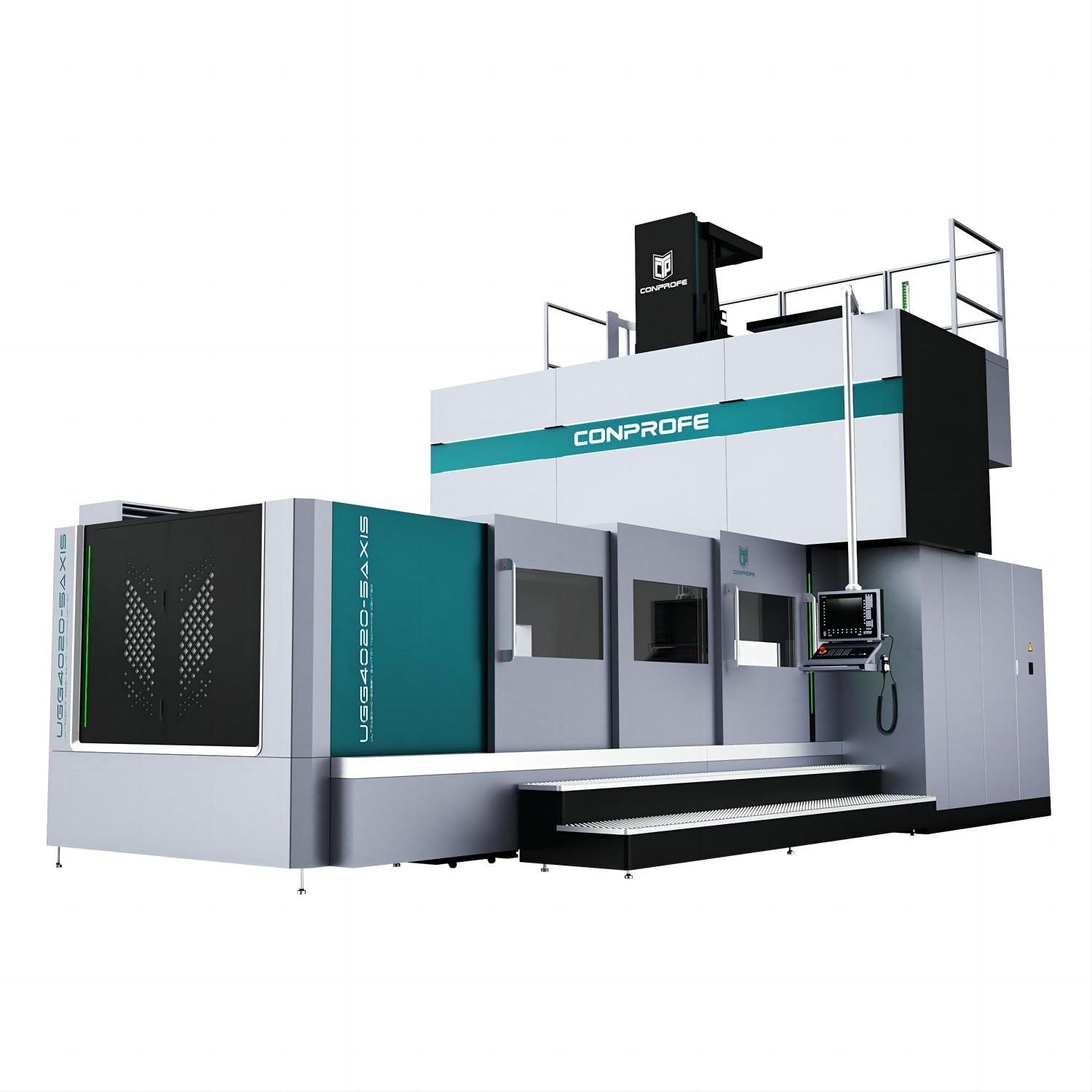

▪ Four types of structure optional ▪ With extensive travel, capable of machining medium-large parts ▪ Fully-enclosed protection optional

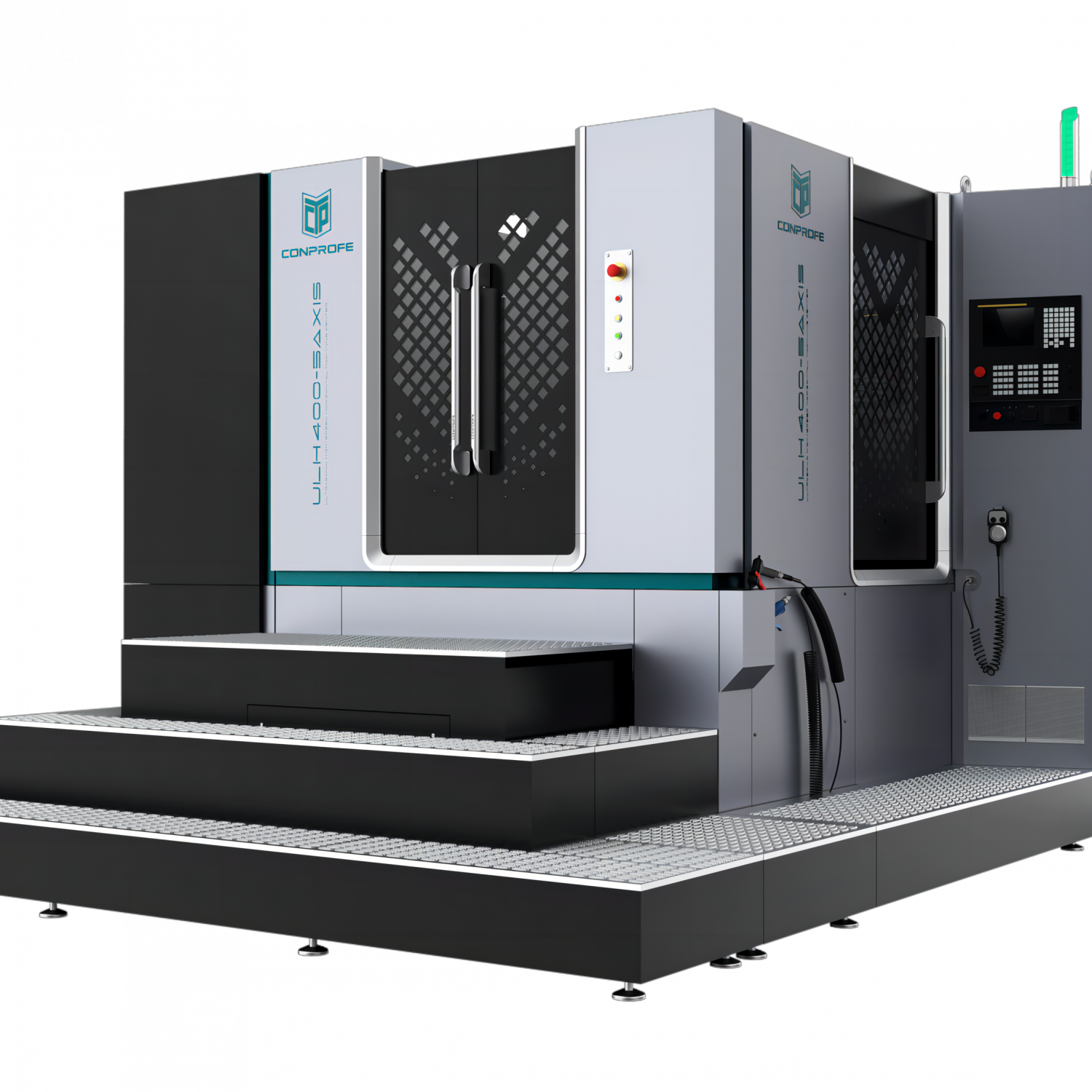

▪ With T structure and low gravity center ▪ Seamless Switch between Vertical and Horizontal machining modes ▪ With chain type tool magazine, capable of holding 24~180T

Semiconductor

Aerospace

Medical

Consumable Electronics

Automotive

General Precision Manufacturing

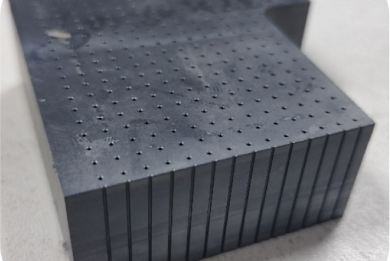

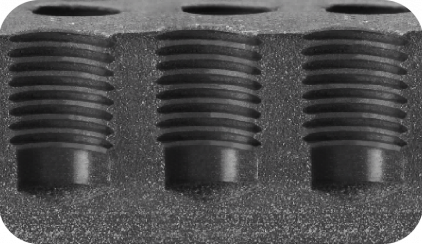

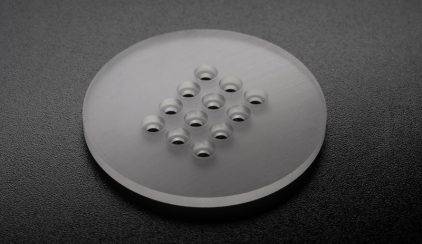

Single Crystal Silicon Showerhead Hole Drilling

Benefits:

+ Continuous machining of over 1,000 D0.45x23mm ultradeep holes

+ No obvious chipping around the hole edge

+ Hole roundness 0.003mm

Related Cases

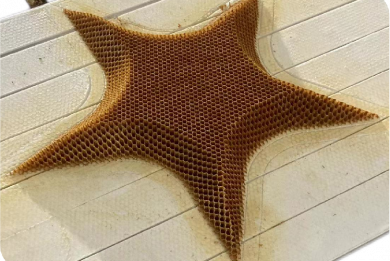

Nomex Honeycomb Contouring

Benefits:

+ Burr reduction by 90%

+ Efficient 5-axis contouring of complicated shapes

+ Optional fully-closed protection and vacuum system against dust and explosion

Related Cases

Titanium Alloy Lumbar Fusion Cage Machining

Benefits:

+ Cycle time down by 50%+ from 25min to 12min

+ Tool life up by 50%+

+ Surface roughness Ra<0.6μm

Related Cases

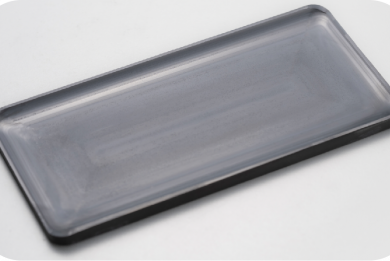

Aluminum Laptop Cavity Machining

Benefits:

+ Cutting force reduced by ultrasonic-aid machining

+ Chipping decreased from 0.229mm to 0.02mm, a reduction of 91%

Related Cases

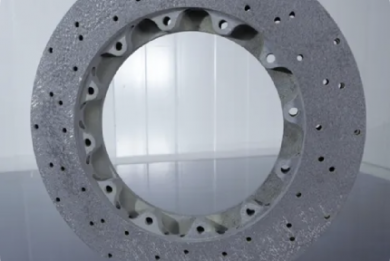

Carbon-Ceramic Composite Machining of New Energy Vehicle Brake Disc

Related Cases

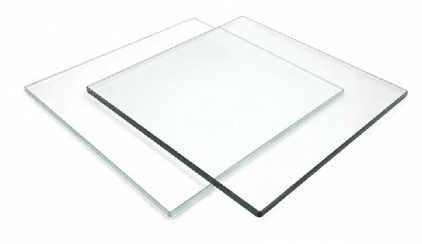

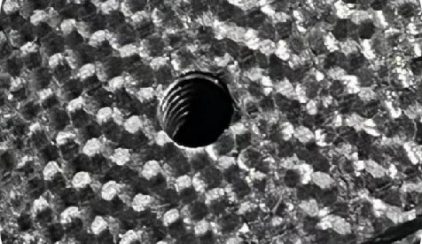

Quartz Glass Fiber Preform Pre-stressed Hole Machining

Benefits:

+ Hole wall roughness 0.122~0.232μm with ultrasonic machining

+ Hole parallelism <0.0385mm (vs. required<0.8μm)

Related Cases

PEEK Cervical Cage Machining

Titanium Alloy TC4 Cervical Spine Plate Milling

Tibial Polyethylene (PE) Insert Machining

3D-Printed Titanium Alloy Artificial Skull Milling

Curved Profile Machining of Aluminosilicate Glass

Sapphire Through-Hole Sidewall Machining

Titanium Phone Enclosure Machining

Titanium Tablet Enclosure Machining

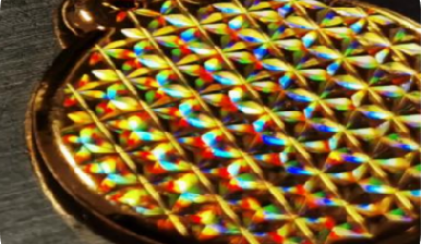

Colorful Automotive Wheel Hub Machining

Silicon Carbide Chucks

COMPANY INTRODUCTION

- For more than 20 years, Conprofe has strived to differentiate itself from many CNC suppliers by developing its unique machining centers and innovative solutions for hard-to-cut and hard-brittle materials through its patented Rotary Ultrasonic Machining (RUM) and MQL/ScCO2 cooling technologies.

- Experience the difference with Conprofe and discover how our innovative approach to ultrasonic machining can propel your business to new heights. Also, as a leading China CNC machine manufacturer, we’re looking for CNC machine dealers. Contact us today to discuss your project requirements and unlock the full potential of precision engineering.

CONPROFE COMPETITIVE ADVANTAGES

Advanced Technologies

Innovative solutions for hard-to-cut materials through its CNC machines equipped with Rotary Ultrasonic Machining (RUM) and MQL/ScCO2 cooling technologies

Experience

Over 20 years, Conprofe’s R&D team has developed 850+ technology patents for its advanced Ultrasonic-Green Machine Tools

GET FREE QUOTES

GET FREE QUOTES

Agents Wanted

Esther Hu | Senior Director, International Sales & Marketing

Tel: +86-138 2607 9999

E-mail: esther.hu@conprofetech.com

NEWS

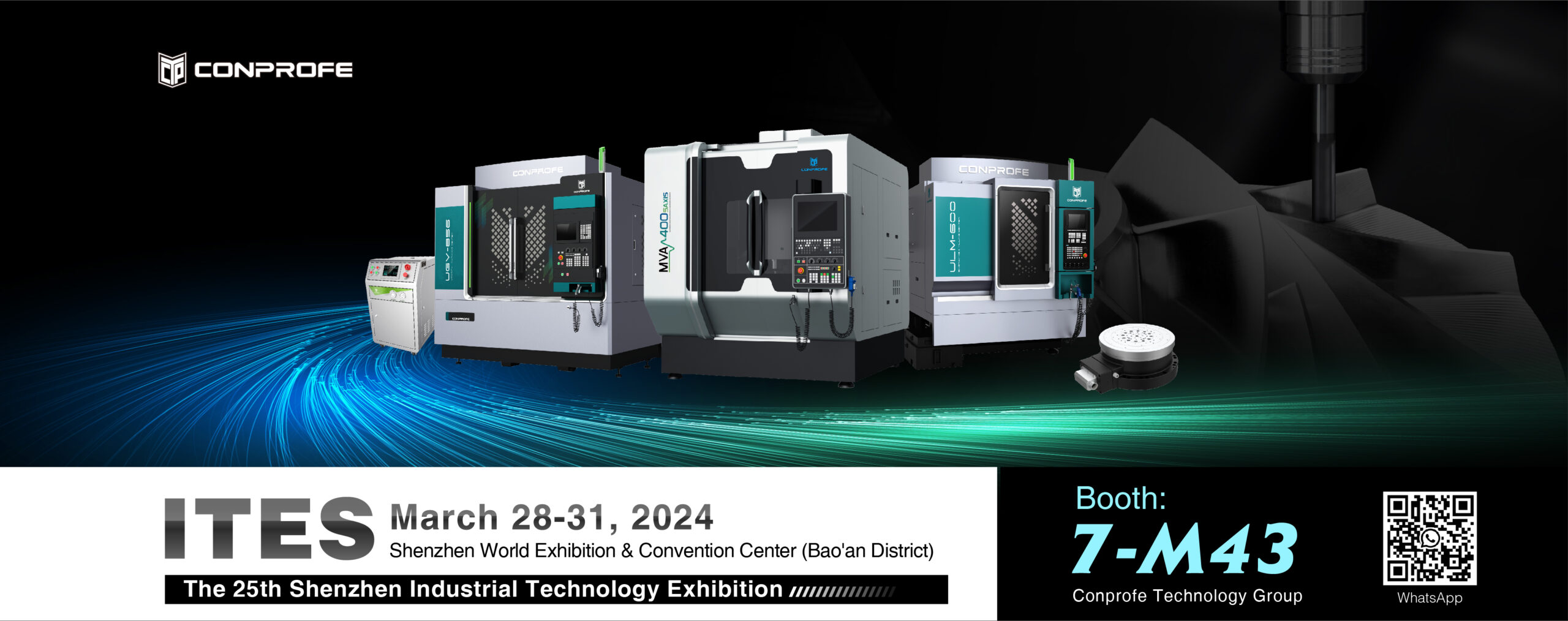

China CNC Machine Tool Fair 2024 (CCMT)

Visit us at CCMT booth E5-A111 from April 8 to 12!Registration: https://lnkd.in/gpCqXbKq

Visit us @ SITMOS Exhibition | Booth 05A730 | April 1-5, Seoul

Date: April 1-5, 2024 Venue: KINTEX Booth No.: 05A730 Join Conprofe at SIMTOS, Korea’s premier

Multiple Events Approaching! Come Visit Us to Discover Efficient, Green and Intelligent Solutions!

SEMICON CHINA SEMICON China 2024 is the largest annual event in semiconductor industry across the